Transform Your Production Line with AGen Software

Transform Your Production Line with AGen Software

Transform Your Production Line with AGen Software

(Streamline operations, boost quality control, and gain real-time tracking for a smoother, smarter production process.)

Introduction

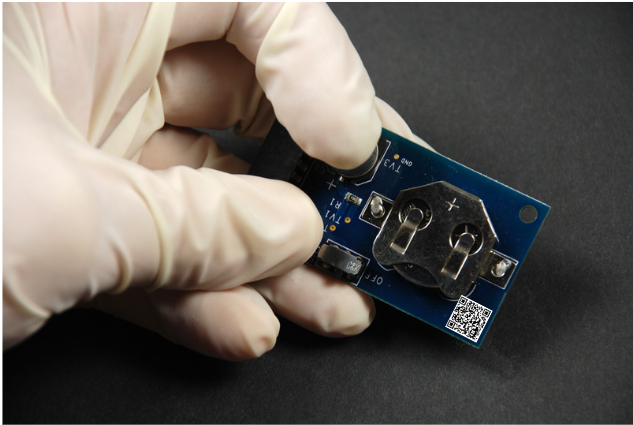

A production line is a structured manufacturing process that moves products along a series of workstations for assembly. This approach is particularly common in the machinery industry, where each station focuses on specific assembly tasks to build complex equipment efficiently. For complex products, smaller subassemblies, such as circuit boards or individual components, are often assembled separately before being integrated into the main production line.

Why is AGen Software essential for production line workstations?

AGen is a web and mobile-based program generator and data analysis application that allows companies to customize their data capture needs on demand. It addresses challenges such as component variability, which can slow production, by enhancing quality control and enabling early defect detection in small parts, thus reducing rework costs.

The software’s precision tools ensure accurate assembly, minimizing alignment errors that affect functionality, while also streamlining inventory management to prevent shortages and excess stock. Additionally, AGen standardizes operations to mitigate skill variability among operators, monitors equipment health to reduce downtime, and provides advanced testing capabilities for thorough inspections.

What does a workstation using AGen Software look like?

1. Raw Material Supply: Materials are tagged with QR codes and scanned using Zebra scanners. This data is instantly logged into AGen Software, keeping real-time inventory updates.

2. Assembly Preparation: Components are organized and scanned to mark readiness in AGen Software. Visual guides on screens display parts lists and steps, making setup fast and accurate.

3. In-Line Quality Checks: Quality checkpoints equipped with Zebra scanners and inspection tools verify quality at critical stages. Scanning pulls up requirements in AGen Software, ensuring compliance and traceability.

4. Final Assembly: As parts are added, Zebra scanners update AGen Software to mark completion. This step confirms the product is fully assembled and ready for packaging.

5. Packaging: At the packaging station, Zebra scanners capture the final scan, logging shipping details in AGen Software and providing safe, accurate packaging instructions.

Adding AGen Software to your production line makes everything faster, easier, and more reliable. With real-time tracking and automatic updates, you can keep an eye on materials, assembly steps, and quality checks without extra work. By scanning QR codes, AGen keeps a clear record of every step, so you always know what’s happening and can catch any issues early. This means a smoother, smarter production process that helps you meet demand without stress.

Are you ready to make your production line easier and smoother?

Hit us up to know more details!

By:

Stephanie

| Date:

05 Nov2024