title

Introduction

Autotrack On demand Barcode warehouse picking solution is an integrated solution design by Autotrack team which integrated the latest barcode scanning technology and wireless technology. It consists of 2 parts of software include Autotrack on PC/server site and application running on the mobile devices. Autotrack On PC/server will integrate with customer existing inventory control system or ERP and give online information directly to the mobile devices to do picking based on the barcode number and shelf location. The picking process will be either based on picking order, or base on shelf sequence. This always online application will give the clear picking direction for picker to plan and do their picking activity.

What is Autotrack On demand barcode picking solution?

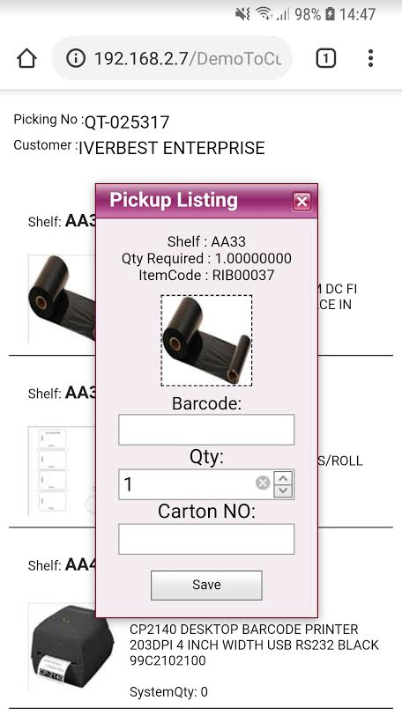

Autotrack On Demand barcode picking solution is an online picking solution offer to the market for the purpose of integrated to your existing sales order system and verify again it to prevent any wrong picking happen during the pick process. Our Autotrack will give a clear indicator for the picker what is the product they need to pick and give clear error indicator for wrong picking activity. The clear product picture will be shown on the picking screen in order for the correct item to be pick and verification process is required by scan on the product barcode. The warehouse manager can give the clear instruction and arrangement for the picking activity by assigning the correct picking task to correct picker.

Who and why Autotrack On Demand barcode picking?

Autotrack On Demand Barcode picking solution offer by Autotrack On Demand team is a very easy to integrate and user friendly solution. We are designing the picking solution specifically target for Small and Medium Industry (SMI) and Small and Medium Enterprise (SME) company in Malaysia and Singapore. This barcode picking solution developed in the purpose to prevent any wrong picking happen during the stock picking process and give a complete picking report to the management for better picking arrangement and future cost saving.

�

How to use Autotrack On Demand barcode for warehouse picking?

3 simple steps involve in Autotrack picking solution to assist you on picking.

Step 1 - Assign the picking task to picker by the store supervisor. This task will make sure the job being distribute evenly by the supervisor and better manpower arrangement can be done to achieve better efficiency.

Step 2- Picking base on assigned task by picker into dedicated picking box before packing at the packing counter. Picker picking process simplified with the cleared display product picture and shelf location. After picked the required item, picker just need to verify by scanning on the product barcode and the carry box barcode to make sure the picking is correct.

Step 3 - By monitoring the picker chart board, supervisor will able to monitor daily picking activity and outstanding task to be complete by the picker, at the same time, it also give the overall outstanding task to be complete by the picker versus the total picking activity.

What inventory control system can Autotrack On Demand work with?

Autotrack On demand Picking solution work with most of the inventory program available in the market as long as the software vendor allow us to read only the database table which contain the sales order information. Alternatively Autotrack can integrate with inventory control system by just reading the text file, excel file, Json connection, or any open database connection (ODBC) available for third parties software reading. Example of inventory system including Autocount accounting and inventory, UBS, EMAS accounting, Million Accounting and Inventory, SAP business One, Oracle, abas, SQL, MYOB, SAGE, Infor, Epicor, Microsoft Dynamics and etc.

What is inside the warehouse picking solution when you purchase from us?

�

Warehouse picking is the process to pick up requested item into the packing container before it being verified and pack into individual packing box by using barcode technology.

Autotrack able to integrate with most of the inventory system in the Malaysia market to provide barcode warehouse picking solution for your warehouse requirement.