| Loading… |

AGen receiving inspection is the basic management process for your receiving department, quick recording tool is useful for this process.

23/Apr/2024

Introduction

AGen Receiving inspection in a warehouse management system refers to the process of managing of inspecting incoming goods or materials upon their arrival at the warehouse. This inspection is conducted to ensure that the received items match the order specifications and meet quality standards set by the organization.

During receiving inspection, warehouse personnel typically verify several aspects of the received items, including:

.png)

Quantity: They count the number of items received to ensure it matches the quantity specified in the purchase order or shipment documents.

.png)

Quality: They inspect the condition of the items to check for any damage, defects, or discrepancies compared to the expected quality standards. Commonly the photo will be taken during the process.

Documentation: They review accompanying paperwork, such as packing slips, invoices, and shipping documents, to confirm accuracy and completeness.

Compliance: They ensure that the received items comply with any regulatory requirements, industry standards, or specific guidelines set by the organization.

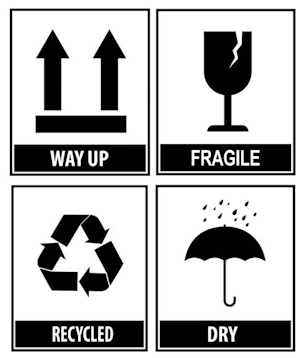

Labelling and Packaging: They inspect the labelling and packaging of the items to ensure they are correctly labelled, properly packaged, and securely sealed for storage or further processing.

Summaries

Receiving inspection plays a crucial role in maintaining accurate inventory records, preventing inventory shrinkage, and ensuring customer satisfaction by minimizing errors and discrepancies in received goods. It helps warehouse managers make informed decisions regarding acceptance, rejection, or quarantine of incoming inventory, thereby contributing to efficient warehouse operations and supply chain management.

|