| Loading… |

Production serial number or batch number generation make simple with QR code, how to do it?

24/Oct/2023

Objective.

The main objective of production batch tracking is to make sure that the product quality control is traceable and able to have the recalling process just in case of any unwanted incident happen on the product.

Advantage

Few important reasons why the factory should apply serial number of batch number for the product, below is the main reason why you should use the detail tracking for your product.

Customer Satisfaction, Supply Chain Efficiency, Streamlined RMA (Return Merchandise Authorization) Process, Compliance and Reporting, Counterfeit Prevention, Customer Support and Recall Management, Warranty and Service Management, Quality Control, Accurate Inventory Management, Improved Traceability.

How to do it?

3 important steps for production batch tracking to be plan and perform are determined batch number format, assign batch number, and print batch numbers. With the proper organization and user-friendly software and hardware, the production batch number can be performed within the split of second without increasing the workload for the production worker.

Who to do it?

The production batch number should be printed by the production department worker instead of warehouse workers. This is to make sure the batch number information is properly recorded under the production management system and not warehouse inventory system. The recorder batch number should be able to use for future supplier tracking and recording purposes.

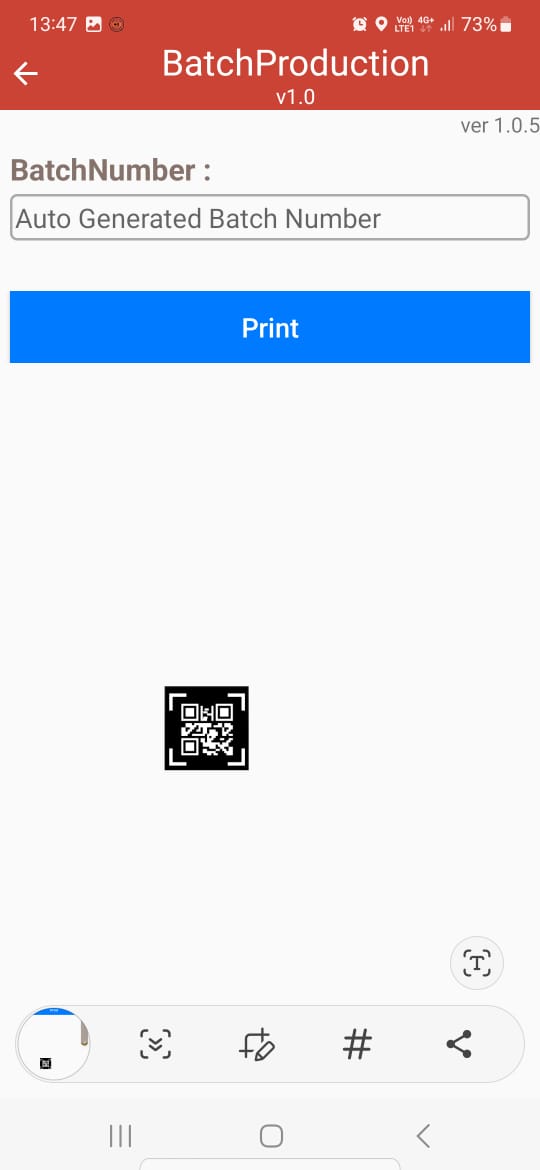

Let start it with your mobile phone.

Step 1 – run the QRcode generation software, click the print button. If your mobile phone connect to the selected label printer, then the batch number will be printed.

Step 2 – Stick the generated label with batch or serial number on the product directly or on the product carton box. Then the batch number generation is done.

Target implementation duration – maximum 2 days.

Step 3 – report viewing and filing for monthly summary purposes.

|