What you need to know and consider when choosing the right

barcode/label printer.

Buying and operating a barcode label printer can be

expensive and time consuming for a company, particularly for the person who are

first time invest in barcode printer. Where are lots of decisions to make all

at once, but the most important one is to start off with the project and

continuous run the project. The AIDC market has some very good honest dealers

who are not only selling the printer but also support after sell and some who

are just trade the printer without after sales service.

It’s easy to buy the wrong thing, but very difficult to sort

out later. You can’t get your money back

from someone who has disappeared and your printer may become "White

Elephant", who will sit down in your office and taking up the rental space

from you. Always remember, no barcode manufacturer makes just only one model in

their factory. Make sure you select the

correct configuration and correct part number, just a single digit different in

the part number may cost the price huge different after the currency

conversation. Below is the specification for you to take note on buying barcode

label printer.

Printing Volume vs speed

vs label size

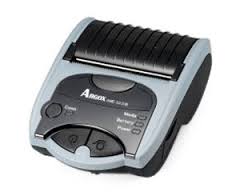

Mobile printer is only recommended for small volume printing

and label size smaller than the 30mm in height with volume not more than

3000pcs/day.

Desktop printer is recommended to the label size

which is smaller than 30mm in height and printing volume at below 5000pcs/day. You

may need to prepare for 1 whole day time for printing up to 5000 pcs label

include the label and ribbon changing time.

Industrial grade printer is recommended to the any

label size and any printing volume. Comparatively high speed to Desktop printer

and bigger label take up roll allow high speed printing and lower label

changing frequency.

To be continuous…