|

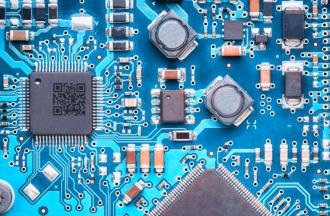

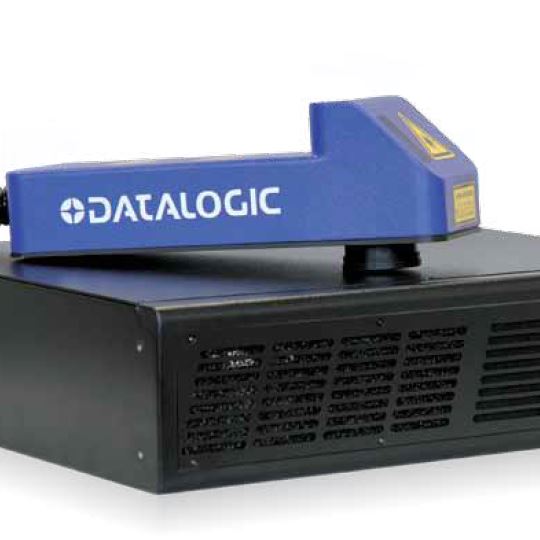

Datalogic Arex 20W with Matrix 220 DPM for track and trace PCB board manufacturing application.

07/Nov/2018

Autotrack On Demand track and trace solution now integrate 3 main component of our product to become the complete solution for your manufacturing PCB track and trace requirement. Base on the quick and easy installation solution, tracking become simple and easy to be implement in your factory production floor. Code validation after marking is a must for today work in progress application. Verification based on barcode verifier specification, the latest matrix 220 DPM give you the top industrial grade identity solution.

How to do marking on PCB board.

Moving conveyor minicon will transfer the PCB in front of the AREX 20 laser marking machine, S60 sensor will inform the present of the PCB board and the AREX will start the marking process. After the marking process, PCB will be inspec with our latest matrix 220 barcode scanner to make sure the barcode is readable. Once it come to next station, the production worker will pick up the PCB and scan with Datalogic Heron scanner for additional working process.

Why you select our track and trace solution?

•Marking on most of the PCB surface.

•Ultra-compact dimensions and custom design for easy integration

•Superior reading performance for very high resolution 2d barcodes (2 mils)

•Possibility to create clusters to cover wide FOVs

•Smart electronic focus control for high reading flexibility

•Reading on rough surfaces or shiny materials

•ESD filter avoiding electrical discharges onto PCBs

•Anti-YAG filter when working closely to laser markers for better reading protection.

•Stable Code Grading embedded in the reading result

•Complete solution reporting on the whole process.

|