Work In progress (WIP) Identity tracking solution offer by Autotrack Team to help manufacturing for tracking the time spend, material use for every station.

12/Mar/2018

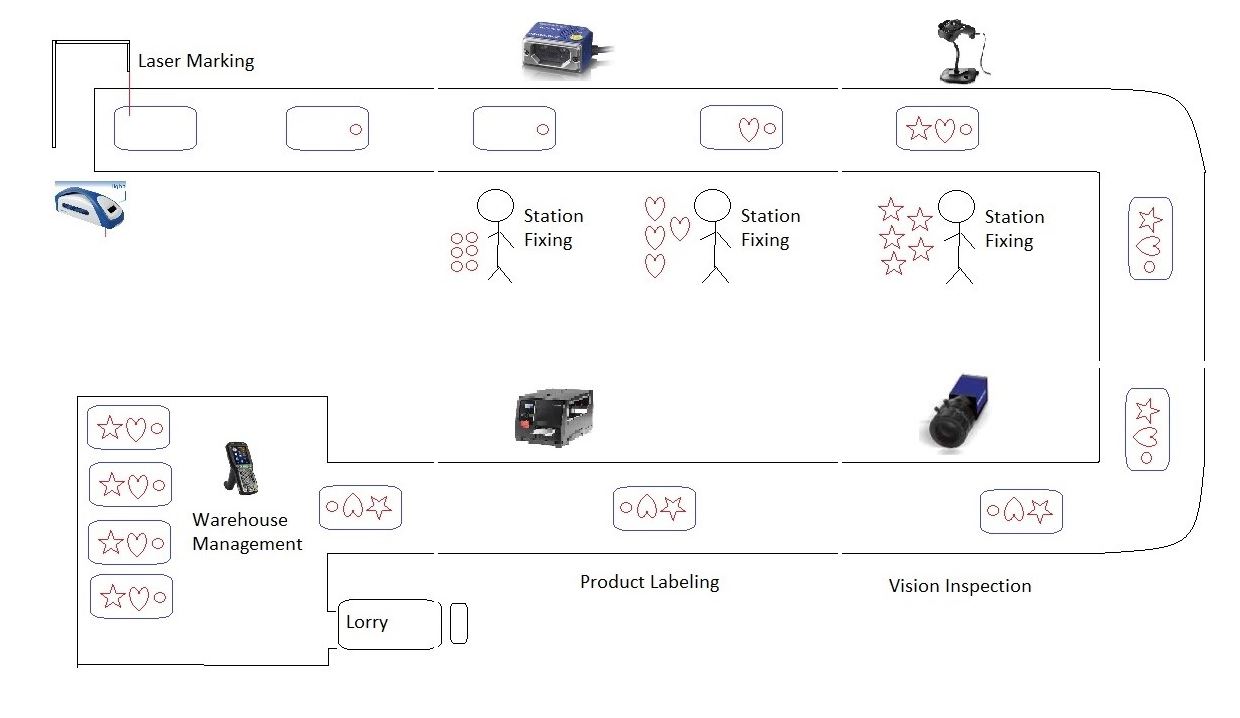

Autotrack Work In progress /Work in process (WIP) gives the manufacturing a complete tracking on process flow by using the product identity. The whole process start with laser marking solution where by customer will mark their product by using laser technology. The marked identity will permanently follow the mark product to next step of fabrication process. The solution give you the complete data capturing by start the identity issuing either by using laser marking or optional to label printing on sticker and apply to the product.

.JPG)

At the next step of the process, the product identity will be capture manually by using manual barcode scanner or will be auto capture the identity with our advance unattended scanning system. The date and time stamp as well as operator identity will be capture as well base on customer requirement. For fast data capturing of fully automated production line, unattended scanning system is a must for the process. optional picture capture after the production step is a good option for quality control purposes.

Along the fabrication process, we also offer you the optional vision inspection solution for detecting any of your surface defect. With the advance camera and artificial intellegent on the computer processing on photo, now Autotrack able to give you the clear information of the product surface defect.

After the fabrication process finish, Autotrack team also give you the solution for your product packaging labeling base on GS1 standard or your company inhouse inventory barcode. Label printing solution is part of the available madule in Autotrack, our solution is ready to print for you the complete shipping label before it being send into store for buffering or send directly to the logistic or customer.

Before you locate your finish product into your warehouse. Autotrack team also selected few different brand of mobile computer for your warehouse purposes including receiving, stock transfer, delivery and stock take.

.JPG)

|